Applying Innovative Desalination Technology for Twentynine Palms Marine Base

The Marine Corps Air Ground Combat Center (MCAGCC) is in the heart of the Mojave Desert, 130 miles east of Los Angeles. Sprawling over 766,000 acres, the facility is the largest live-fire training center for the U.S. Marine Corps, as well as the only combined arms live-fire and maneuver training range complex. The remote location and vast, versatile landscape provide ideal conditions to instruct military personnel year-round. The Surprise Springs Aquifer has provided potable water to the training center since the 1950s, but the facility’s needs exceed the aquifer’s sustainable supply capabilities. Certain wells within the aquifer also contain elevated levels of iron and hexavalent chromium which require treatment to meet California’s current and proposed drinking water standards.

The steady demand for potable water, compounded with quality issues affecting certain wells, presented the Naval Facilities Engineering Command (NAVFAC) with a challenge: the need to add an alternative groundwater source for MCAGCC to ensure the future viability of this critical military asset. NAVFAC called on CDM Smith to design and build a new water treatment plant that can provide high-quality drinking water for the MCAGCC and extend the viability of the aquifers that supply the base with groundwater. The 3 mgd RO-CCRO treatment plant incorporated key elements of design-build construction to successfully deliver a facility incorporating a high recovery treatment train that will maintain a reliable supply of potable water to the base for years to come.

A state-of-the-art water treatment plant

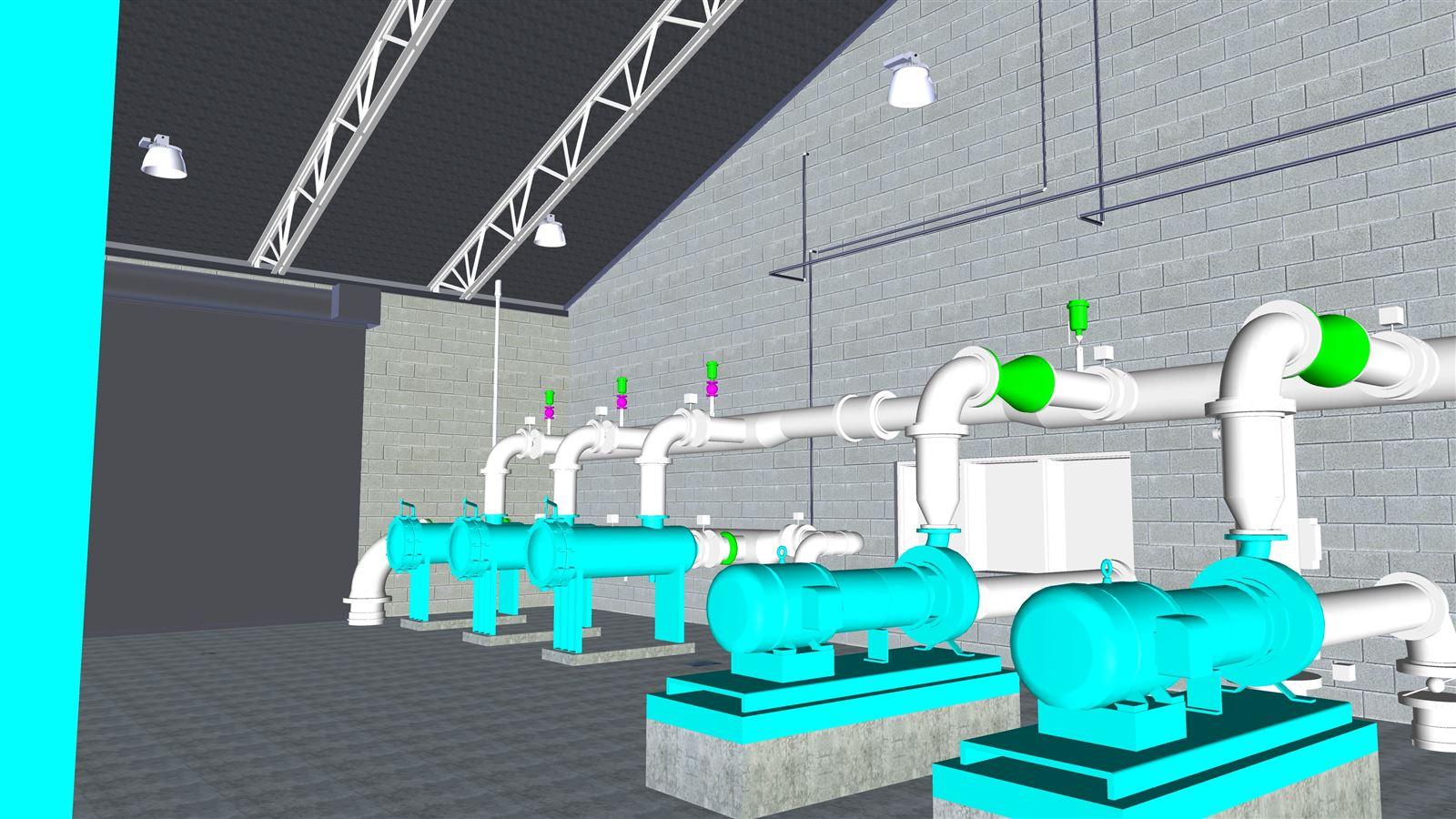

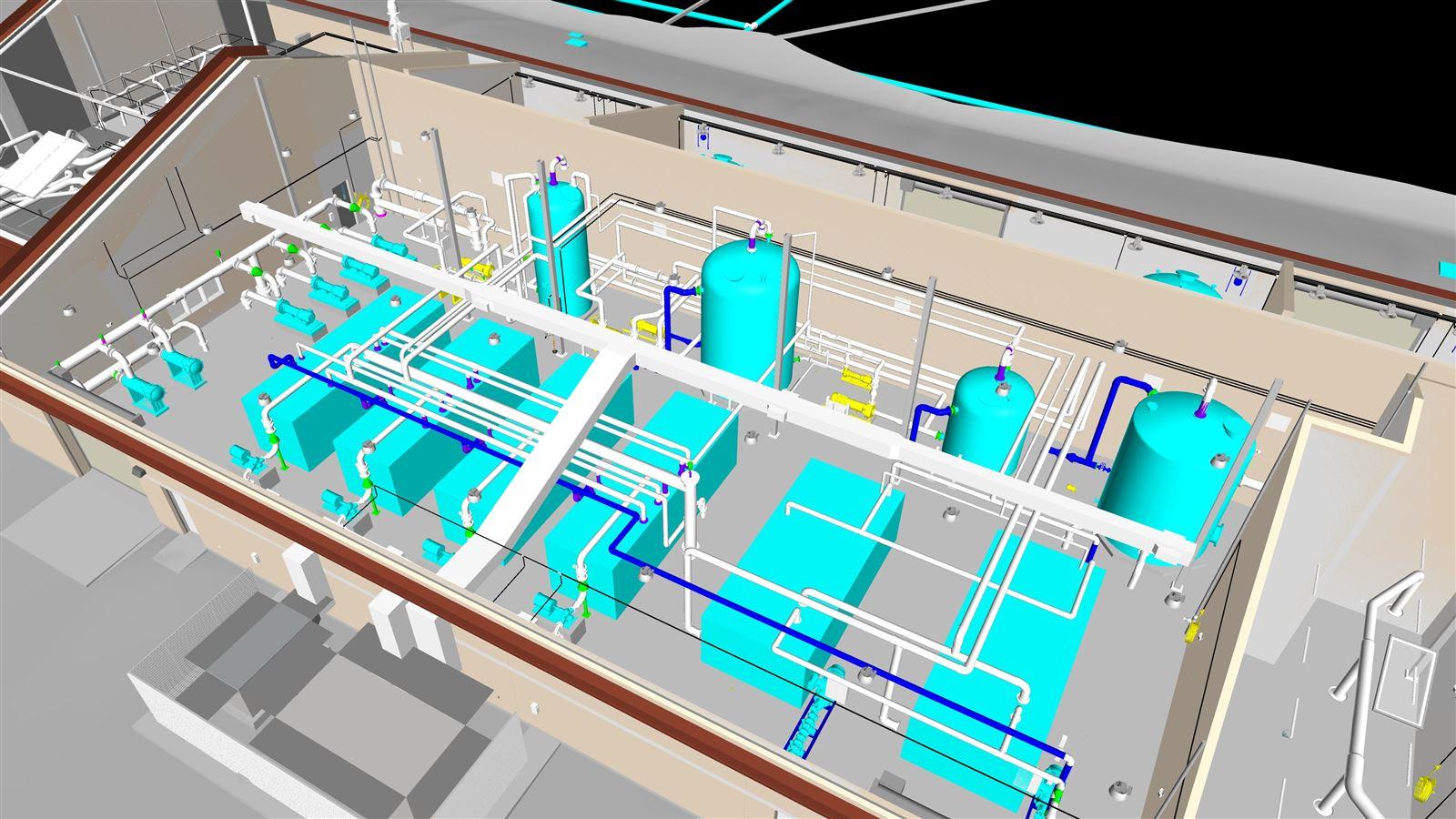

The new WTP building has distinct yet integrated areas for control plus administration and laboratory, main process treatment, chemical storage and feed, maintenance, and electrical equipment.

The novel treatment train is comprised of a 2-stage RO system along with CCRO operating as a brine recovery process. The 2-stage RO operates at a recovery of 75% while the CCRO achieves 76% recovery. This results in an overall recovery of 94%. The use of CCRO to treat RO brine is a relatively new concept in municipal water treatment and was employed on this project to maximize the recovery rate that could be sustainably maintained when treating water from the Deadman Aquifer. Maximizing recovery minimizes the volume of brine disposal required in this remote location. The design approach accounted for operational considerations including bypass blending to reduce overall post-treatment chemical costs, equipment accessibility within a cost-effective compact footprint, process monitoring, and all key personnel health and safety protection features. As the WTP is located in the desert, and far from the Base’s main infrastructure, extra efforts were needed to reduce any waste streams requiring hauling off-site.

New production wells

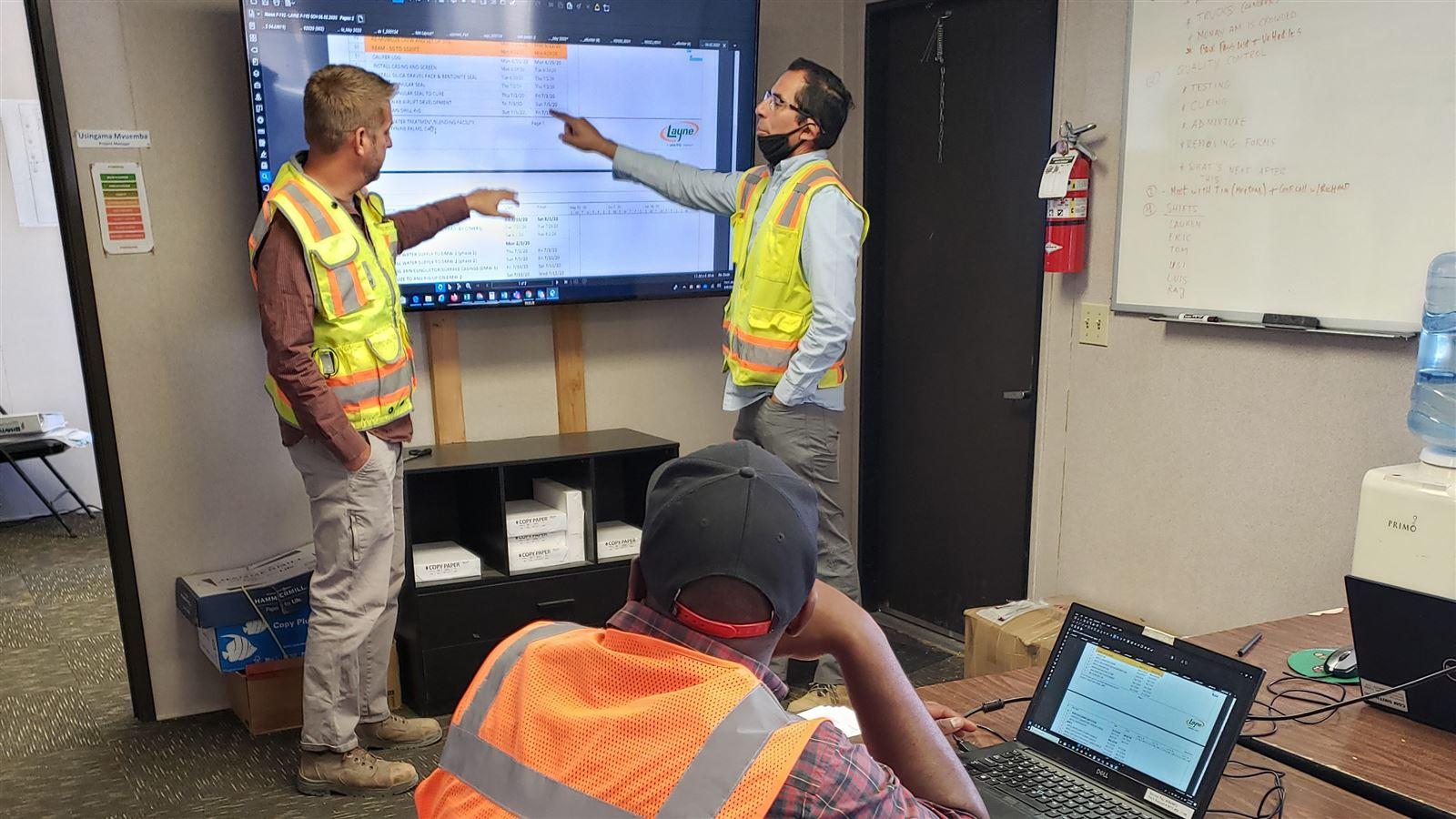

To meet the growing water demands of MCAGCC, the team developed two new wells from a new water source: the Deadman Aquifer. The 1,000-foot deep groundwater source wells augment 11 current wells in the Surprise Springs Aquifer to produce a reliable source water supply for the facility. The new wells required careful planning and sequencing, with drilling and testing completed prior to confirming mobilizing to the next site. CDM Smith and a subcontractor worked together to drill and permit the new wells with a California-certified hydrogeologist on site to confirm specifications were met. In addition to the new wells, new controls were added so that the existing Surprise Spring wells could be operated remotely via the new WTP’s SCADA system.

Transition pipeline and water storage

One mile of new 16” fusion bonded high-density polyethylene buried pipelines convey groundwater from the new Deadman Aquifer wells and redirect Surprise Spring Aquifer groundwater to a new 1-million-gallon source water blending tank. The project team’s solution included yard piping configured to accommodate multiple bypass options: full tank bypass, full plant bypass, and controlled bypass for blending of Surprise Spring Aquifer water and treated water. The new source water blend tank features welded steel construction, an impressed current cathodic protection system with inlets for source water, an internal mixer, and an outlet to supply blended water to the WTP.

As limited natural resources continue to challenge our military installations, high-recovery water treatment increases utility resiliency and independence for long-term sustainability to meet their mission objectives.

Evaporation ponds

The team also equipped the plant with two lined evaporation ponds (EPs) to eliminate offsite liquid waste discharge of brine. Each pond included four floating mechanical evaporators to enhance evaporation and reduce the area required to manage the brine flow. Both EPs were sized based on an average brine flow of 85 gallons per minute corresponding to an average plant production of 1.92 mgd and 94% recovery. CDM Smith’s process design allowed for RO flush water to be recaptured and treated by CCRO resulting in reduced flows to the ponds and maximized utilization of the groundwater. To meet California Regional Water Quality Control Board permitting requirements, the lined ponds were equipped with dual-zone monitoring systems and three monitoring wells to provide a robust leak detection program.

Clean water for MCAGCC

Aside from the built infrastructure, technological improvements helped advance the carefully integrated and fully automated WTP. CDM Smith self-performed the programming for the WTP’s industrial control system, including a continuous process and monitoring control functions for the plant, the Deadman Aquifer wells and the Surprise Spring Aquifer wells. The plant is also fully compliant with current cybersecurity requirements.

This state-of-the-art high-recovery treatment facility is achieving both sustainable operability and drinking water quality requirements. The remote location of the base, water and energy conservation, and ease of operations were incorporated into every aspect of design-build project to provide clean drinking water to MCAGCC while meeting current and proposed water quality standards.

As limited natural resources continue to challenge our military installations, high-recovery water treatment increases utility resiliency and independence.