State-of-the-Art SCADA System Returns Utility Reliability

The SCADA system that the Lexington-Fayette Urban County Government (LFUCG) relied on to operate a network of 80 pump stations and two wastewater treatment plants had operated reliably for nearly 20 years. However, time was taking its toll as replacement parts were increasingly difficult to find and much of the system was obsolete. Many of the existing SCADA computers and HMI software running the plant’s monitoring system were old and in the need of replacement. Following a needs assessment, LFUCG decided to upgrade the electrical and SCADA systems at the Town Branch and West Hickman Creek wastewater treatment plants– and replace all 80 remote terminal units (RTU) at each pump station.

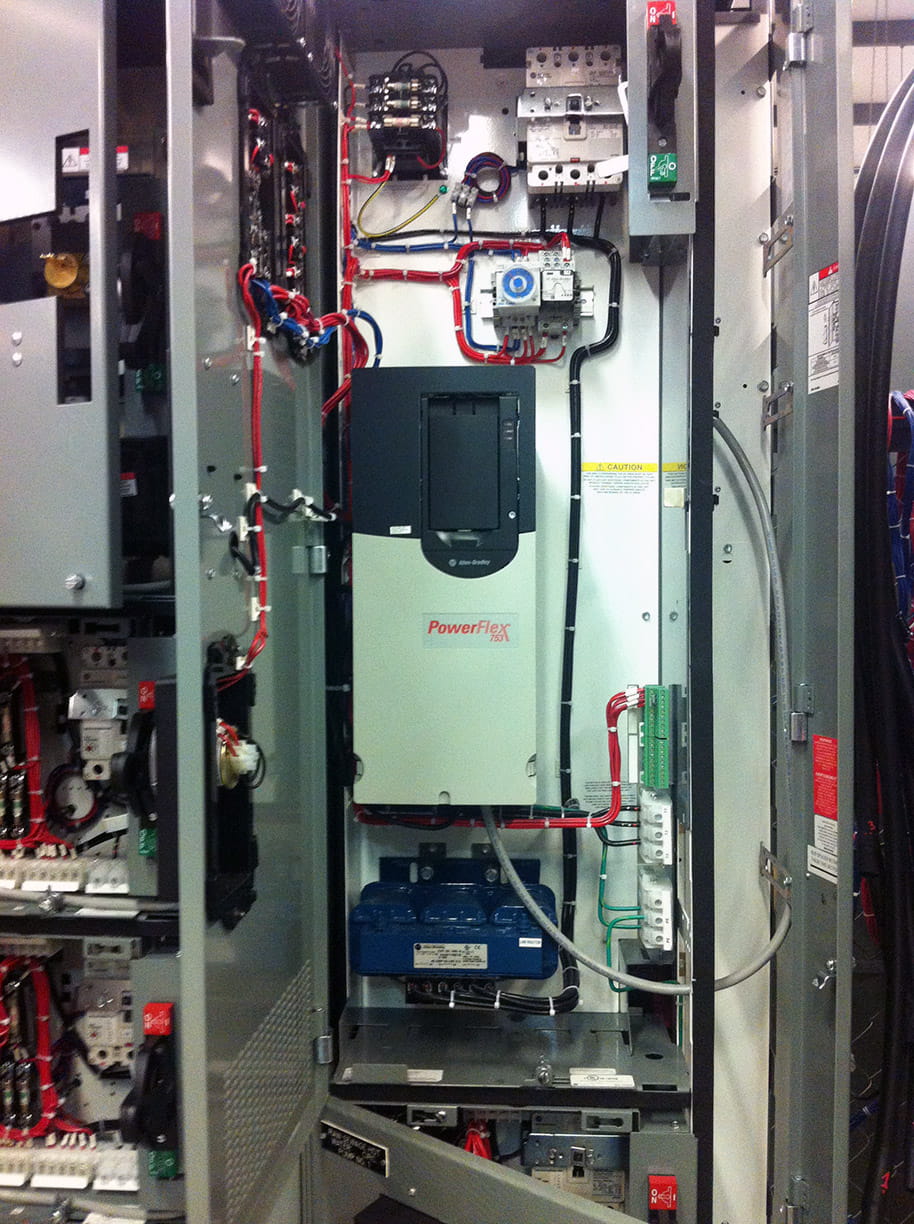

Smart motor control centers (MCC) were manufactured and fully tested and then shipped for installation. All MCC equipment was connected to a DeviceNet network and issues were resolved prior to shipment, eliminating issues in the field during installation.

Smart motor control centers (MCC) were manufactured and fully tested and then shipped for installation. All MCC equipment was connected to a DeviceNet network and issues were resolved prior to shipment, eliminating issues in the field during installation.CDM Smith evaluated the existing telemetry system; provided recommendations for replacing equipment; and evaluated several pump stations, the repeater and antenna location, and the overall polling software/hardware. As a result of this evaluation, LFUCG proceeded with a full design for the replacement of existing hardware at 80 pump station sites. As part of the design, our team developed a strategy so that all sites remained in operation during the entire switchover process.

Improvements included the use of state-of-the-art SCADA equipment at both wastewater treatment plants for reliability, standardization, and long-term maintainability; SCADA control functionality for West Hickman (the existing SCADA system monitored plant operation only); and upgrade the existing proprietary RTUs with a Rockwell RTU-based system and the radio communication equipment.

The new SCADA system design provides multiple benefits, including simplified operations, hardware/software standardization across the entire organization, new control schemes, ability to easily accommodate future growth, readily available support and spare parts, and hardware/software flexibility through open architecture products. Additionally, the new systems allow remote control and advanced automated strategies at LFUCG’s WWTPs and pump stations like coordinated pump station operation, and improved staff productivity. Other benefits include conservation of staff time and energy, improved reliability, enhanced decision-making, and storm preparation and recovery support—helping prepare LFUCG for the next two decades of service.